Promoted by the International World Project Inc, based in Lisbon, it has the objective of creating a highly technological Agro-Industrial pole aimed at the production, processing, packaging and trade of agricultural products.

This is a preview, click on the button to view the full version of the document

Aeroponics is an indoor cultivation system, in a greenhouse or in a grow box, where plants are grown without using soil, thanks to special systems characterized by a supporting structure, mesh pots in which the plants are placed, nutrient solutions based on water and mineral fertilizers and air pumps. These pumps are used to nebulize the liquid solution, which – thanks to the action of the air – can reach the roots of the plants and nourish them deeply. Thanks to the aeroponic technique, it is possible to obtain ideal development conditions for plants. On one hand, the closed and isolated environment compared to the outside will make the cultivated plants much less subject to the aggressions of fungi and diseases, on the other hand, the roots will have a high level of oxygenation and will therefore be able to grow quickly with a minimum amount of water and mineral salts. Unlike in hydroponic cultivation, the plant is not irrigated – in the traditional sense of the word – with nutrients, but suspended in a mesh pot from which the roots will emerge, and will be periodically sprayed with nutrients. This system allows you to consume even less water than is generally used in a hydroponic growing system, because it is recovered and put back into the circuit thanks to a recovery system. Aeroponics is particularly indicated for all those crops which can develop vertically – thus avoiding the exploitation of soil – and less for crops which need wide spaces, such as wheat and corn.

In an aeroponic system the plants grow out of the soil, are continuously irrigated with the system of nebulization, thanks to an immersion pump, in a completely controlled environment in which it is very difficult the presence and spread of pests and diseases, typical of the cultivation in the ground. Thanks to the constant and precise monitoring (with special instruments) of the fundamental environmental parameters (illumination, nutrition, temperature, humidity, pH and conductivity) it is possible to obtain much better results than with normal cultivation in the ground. All this without having to use – as happens in traditional crops – insecticides and pesticides potentially harmful to human and plant health (and with its consequences on the environment). We would also like to remind you that the technique of indoor cultivation using the aeroponic method allows to obtain extraordinary results in terms of speed and quantity, but also in quality

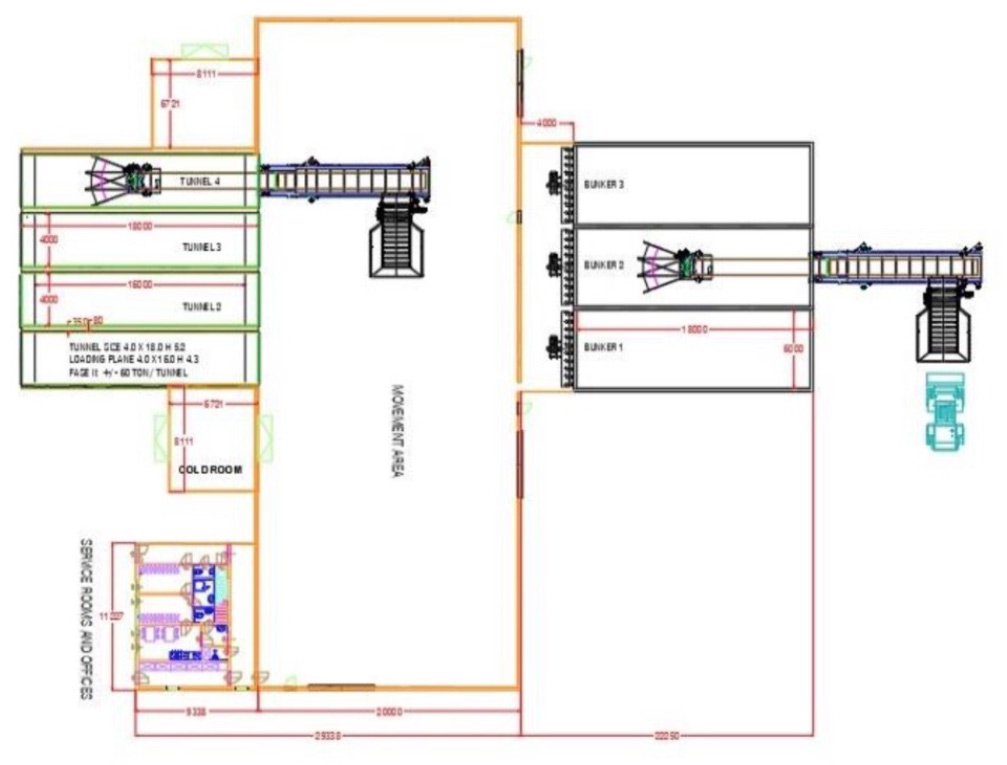

The production unit is in turn composed of three compartments:

Preparation of cultivation beds

The optimal period for the interment of the breads in open greenhouses, goes from September to April; this period can vary in relation to the seasonal trend and to the cultivation areas. The methodology of cultivation of Cardoncello provides that the area cultivated for the production of mushrooms is properly protected from the sun with a 70-90% shading net, supported by normal tunnel arches. In order to protect from the wind, especially in springtime, mats or polyethylene sheets about 1 meter high can be placed around the greenhouse. In the area protected by the tunnel are obtained more ‘beds of cultivation, one meter wide and spaced between them by a corridor of passage. These beds can be obtained using metal boxes so as to create a containment wall about 25 cm high. The beds can also be placed on two levels. Inside the cultivation beds are placed the packages of incubated substrate and covered with a layer of soil (medium-textured soil with neutral pH) about 2 cm thick; it is important that the substrate is uniform. A small overhead irrigation system must be mounted inside the tunnel to keep the area constantly moist. Above the net, especially in autumn and winter, it is advisable to spread a polyethylene sheet to protect the cultivation from sudden and excessive rains that could damage the production.

After three weeks the first harvest

Cultivation beds must be kept constantly humid avoiding water excesses that could induce rotting phenomena. After few days from the burying of the substrate, on the surface of the cultivation beds begin to appear the first carpophores, which will reach maturation after about 25 days from the planting of the substrate itself; after about one week from the first harvest there is the second mushrooming, which must be harvested when ripe: practically the whole cultivation under favorable climatic conditions is completed in about 60-70 days and allows 2-3 harvests. The ideal conditions for a successful cultivation are temperature not higher than 20°C (68°F), high air humidity and calm wind. Factors that influence the productive course of the cardoncello mushroom (lengthening the productive cycle) are the thermal excursions and the persistence of cold periods. When the cultivation is exhausted, the substrate must be removed from the cultivation beds and a second burial can be carried out, after a careful cleaning of the areas themselves with a disinfectant spray based on copper and sodium hypochlorite at 2%. From the point of view of marketing it is very important to plan the sowings. It is necessary to guarantee a continuity in production, avoiding that the production, difficult to preserve, is concentrated in one period. The market requires in fact high quantities distributed during the whole production period. The substrate is prepared between May and December and it is the first matter used for the cultivation of the mushroom. It is a mixture of straw and agricultural byproducts which is chopped and sterilized. The substrate, cooled and collected in rolls closed in polyethylene bags and weighing about 4 kg (from which comes 1 kg of mushroom production), is then inoculated with spores and placed in incubation cells for 80-120 days. At the end of this period the cakes are ready to be planted. During production it is necessary to pay attention to the possible appearance of molds (gen. Dactylium), which starting from the ground (from the remains of mushrooms previously collected and from other organic materials such as: straw, roots etc.) invade carpophores making them unmarketable. In this regard, it is advisable to avoid placing wooden boards or straw or other similar material along the pathways. Other parasites which can cause considerable damages are the larvae of some Diptera which penetrate inside carpophores digging a remarkable number of galleries with consequent depreciation of the product, or they stay in the basal portion of stems and superficially affecting the substratum. At the moment the disease that can create more problems during the production of mushrooms is due to the attack of a bacterium (gen. Pseudomonas), which manifests itself first with the partial or total yellowing of carpophores, then with a subsequent rotting of the same. The affected mushrooms, particularly in an advanced stage of the disease, give off a characteristic smell of putrid substance.

After three weeks the first harvest

Cultivation beds must be kept constantly humid avoiding water excesses that could induce rotting phenomena. After few days from the burying of the substrate, on the surface of the cultivation beds begin to appear the first carpophores, which will reach maturation after about 25 days from the planting of the substrate itself; after about one week from the first harvest there is the second mushrooming, which must be harvested when ripe: practically the whole cultivation under favorable climatic conditions is completed in about 60-70 days and allows 2-3 harvests. The ideal conditions for a successful cultivation are temperature not higher than 20°C (68°F), high air humidity and calm wind. Factors that influence the productive course of the cardoncello mushroom (lengthening the productive cycle) are the thermal excursions and the persistence of cold periods. When the cultivation is exhausted, the substrate must be removed from the cultivation beds and a second burial can be carried out, after a careful cleaning of the areas themselves with a disinfectant spray based on copper and sodium hypochlorite at 2%. From the point of view of marketing it is very important to plan the sowings. It is necessary to guarantee a continuity in production, avoiding that the production, difficult to preserve, is concentrated in one period. The market requires in fact high quantities distributed during the whole production period. The substrate is prepared between May and December and it is the first matter used for the cultivation of the mushroom. It is a mixture of straw and agricultural byproducts which is chopped and sterilized. The substrate, cooled and collected in rolls closed in polyethylene bags and weighing about 4 kg (from which comes 1 kg of mushroom production), is then inoculated with spores and placed in incubation cells for 80-120 days. At the end of this period the cakes are ready to be planted. During production it is necessary to pay attention to the possible appearance of molds (gen. Dactylium), which starting from the ground (from the remains of mushrooms previously collected and from other organic materials such as: straw, roots etc.) invade carpophores making them unmarketable. In this regard, it is advisable to avoid placing wooden boards or straw or other similar material along the pathways. Other parasites which can cause considerable damages are the larvae of some Diptera which penetrate inside carpophores digging a remarkable number of galleries with consequent depreciation of the product, or they stay in the basal portion of stems and superficially affecting the substratum. At the moment the disease that can create more problems during the production of mushrooms is due to the attack of a bacterium (gen. Pseudomonas), which manifests itself first with the partial or total yellowing of carpophores, then with a subsequent rotting of the same. The affected mushrooms, particularly in an advanced stage of the disease, give off a characteristic smell of putrid substance.

Pleurotus ostreatus – Pleurotus nebrodensis (Inzengac)

Nutritional information for 100g of fresh product: Protein 10-30%. Vitamin C 30-144mg/100g . Vitamin B3 (Niacin) 109 mg/100g. Vitamin B9(Folic Acid) 65 mg/100g. Potassium 306mg/100g.

Storage (Shelf Life) 7-10 days; kept in a paper bag at refrigerated temperature 2-4°C.

Nutritional information for 100 g of dry product: Energy value 276 Kcal/100g s.s. Protein 11,95 g/100g d.s. Fats 7,5 g/100g r.s. Carbohydrates 39,85 g/100g dry. Fiber 28,45 g/100g dry. Moisture 70%.

Storage (Shelf Life) more than 15 days; kept in a paper bag at refrigerated temperature 2-4°C

Production Potential Analysis:

Productive calculation parameters:

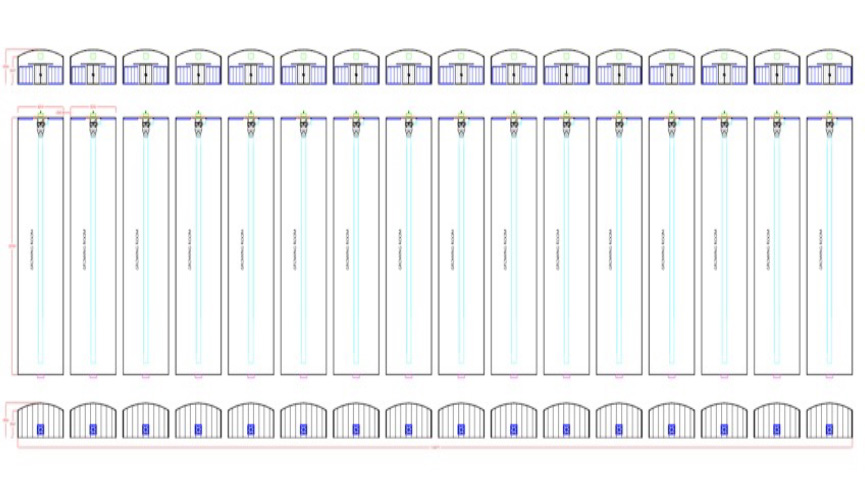

No. 16 cultivation tunnels with a surface of 254 square meters each. Compost load of 280 quintals per tunnel per two months. Total annual load 26.880 quintals of compost.

Estimated production 27/32% – conservatively rounded up to 27%. Annual mushroom production quintals 7,257, or 604 quintals month.

Production value:

Pleurotus Ostreatus:

Total mushroom production 7,257 quintals; assumed sale Euro/kgr. 2.20 (average price between first, second and third choice). Kgr. Sold annually 725,700.

Presumed (but extremely realistic) annual turnover Euro 1,596,540. Turnover with optimal production at an average price of 2.5 Euro/Kgr 1,814,250.00

Pleurotus Cardoncello and Chiodini Mushrooms:

Estimated production 241,000 Kgr; production value Euro year 1,084,500.00 (estimated average selling price Euro/Kgr. 4.50).

Only since the 1950’s mushroom cultivation has used more modern techniques, by using properly air conditioned rooms or cells, soils made of wheat straw, pasteurized and covered with peat. The cultivation cycle of the complete champignon mushroom lasts 100-120 days and can be repeated 2-3 times in a year. To the kingdom of mushrooms belong heterotrophic organisms whose reproductive means consists of spores emitted from the gills of the cap. The fruiting body of the mushroom (the edible part) consists of a stalk and a cap or carpophore, while below the stalk in the soil there is a vegetative structure organized in cells forming filamentous and branched structures called hyphae or primary mycelium which do not differentiate into tissues.

Also known as prataiolo mushroom or white mushroom, champignon mushroom, whose scientific name is Agaricus bisporus, belongs to the Agaricaceae family. There are four different groups of varieties subdivided according to the coloration of the cap: white varieties; brown varieties; intermediate varieties (cream, white-ivory); hybrids. White varieties are characterized by white carpophores, with a delicate surface, usually small in size (4-8 grams). They include strains endowed with greater or lesser speed of production growth. The production of white varieties is mainly destined to the fresh trade. Brown varieties are not much cultivated, they have medium-large carpophores, of a color which varies from light brown to dark brown with a light stem. From researches carried out at the beginning of the century, multispore colonies were obtained and selected in order to obtain the white varieties now widely cultivated. The intermediate varieties (cream, ivory-white) have medium-large fruiting bodies (8-12 grams) similar to those of the brown varieties, light color, presence of brown scales. The gills and spores of mature carpophores are very dark in color. These are varieties suitable for mechanical harvesting. Carpophores, if left to develop, can reach large dimensions. They are not very sensitive to virus infections. In 1976 at the Experimental Station of Horst in Netherlands were started researches aimed at crossing white varieties with intermediate varieties. They obtained hybrids called “Horst U-strain 1-2-3…”. They combine favorable characters of the two varieties such as smooth and white surface, pinkish gills, short stem. The high quality of the hybrids and the good production have favoured a rapid use in mushroom farms. The production is commercialized both fresh and transformed.

Before realizing a mushroom farm, in order to avoid failures, forcing or excessive technical interventions, it is advisable to verify that the area interested in the plantation is climatically suitable for the cultivation of mushrooms. The costs of insulation and labor, in fact, increase considerably where the temperatures are maintained above 25 ° C for long periods. A mushroom farm requires a relatively modest area and it does not matter if it is of little agricultural value. Instead, it is vital that there are no water supply problems. The most important thing in the cultivation of champignons is therefore the substrate. The growing medium should be made of 1/3 wheat or oat straw or barley straw, 1/3 peat and forest soil, 1/3 well-decomposed horse manure, or alternatively: 1/3 well-decomposed horse manure, 1/3 white peat, 1/3 sandy soil. Then the growing medium is placed in wooden boxes or plastic bags and layered (e.g., straw, peat, manure, and peat on top). After having watered the soil abundantly, a phase of fermentation of the stratified mass begins (useful to remove antagonistic bacteria and fungi) lasting 5-15 days, depending on the “freshness” of the manure and the material used. In modern mushroom farms this operation consists in a real pasteurization of the substrate with steam, it is done in special cells with temperature, humidity and CO2 in controlled conditions. Subsequently it is possible to sprinkle the culture medium with mycelia and cover it with some wet peat (the mycelium must be at a depth of 4-5 cm). This phase is called incubation, fundamental are: the humidity that must remain between 80 and 100% (detectable with an appropriate hygrometer) and the temperature that must not exceed 22-23°C. These mushrooms should be watered little and often, the idea is to keep the layer moist and not soaked with water. After about 12-14 days from the incubation, we cover the mushroom bed with a layer of soil in which the mycelium will develop, the temperature is brought to 17°C. After about 10 days we assist to the appearance of the first hats.

Crop care and irrigation

During the period of sprouting and harvesting it is necessary to do the following cultural cares: Watering: for every potential kg of mushrooms it will be necessary about one liter of water per square meter. If this amount seems insufficient, it is advisable not to increase it, but to water twice a day rather than too much at once. It is very risky to distribute water when the carpophores are formed and it should not be necessary to water during the peak of the sprint if it was done at the right time. If the mushrooms are not completely dry by the time they are harvested, they will easily spoil and there is a possibility of bacterial spots appearing on the surface of the cap. Watering procedures for the second harvest are the same of the first one, whereas for the third harvest it will be necessary to pay attention because mushrooms will be lesser in number and therefore water needs will be adapted to the yield.

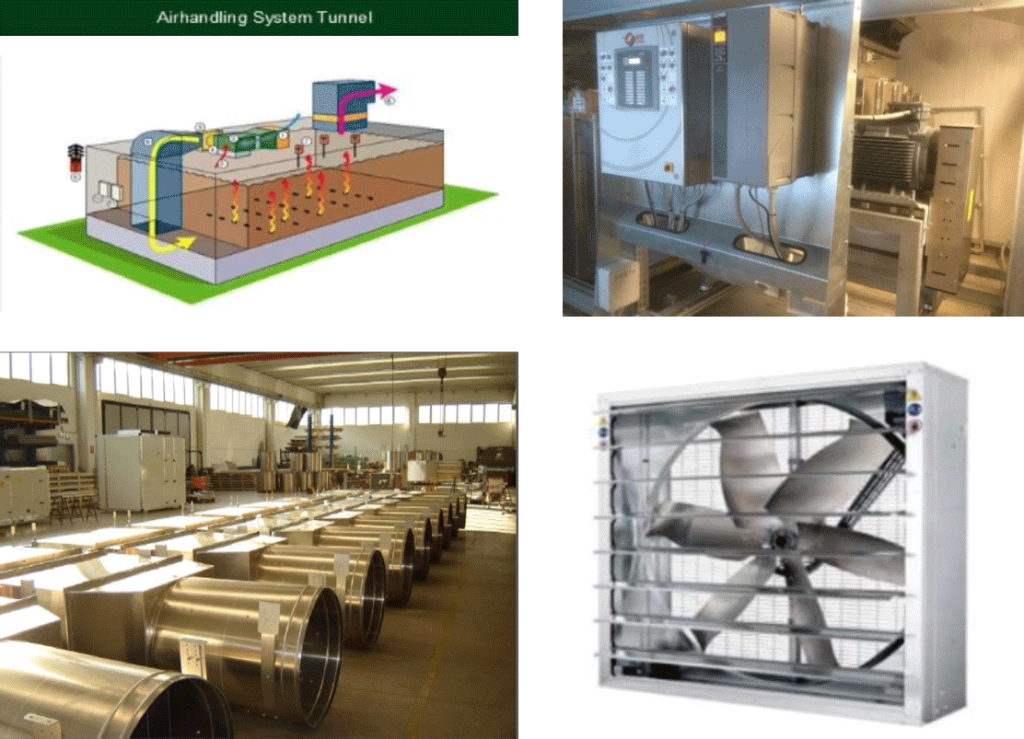

Ventilation: during the whole harvesting period, and especially when mushrooms are very numerous, ventilation must be abundant because between mushroom heads are formed gaseous pockets mainly made of CO2. Moreover, the heat produced in the beds during the marking and formation of carpophores must be eliminated, especially through the evaporation of water from the upper layer of the growing medium.

Temperatures at harvest: During harvest, the air temperature should be maintained at 15-16°C, while the temperature of the beds will be slightly higher. In case of a very abundant sprint, the air temperature should be lowered to 14-15°C. If temperatures are slightly higher, fungi grow faster, but this is at the expense of quality especially during the first sprint because diseases and pests such as rot, web mold, and nematodes develop more rapidly.

The specific adversities of Agaricus bitorquis are mainly caused by bacteria, fungi and various types of viruses. The defense is mainly based on the principles of preventive control by realizing good general hygienic conditions in the environments, with disinfection and air filtration and pasteurization of the substrates used. Still today there are no varieties resistant to diseases caused by moulds, however it has been found that Agaricus bitorquis is very resistant to virosis. Among the moulds indicating wrong agronomical techniques there are, for example, the Web Mildew or Spider Web (Dactylum dendroides) which indicates stagnant air and excessive air humidity or the Yellow Mold (Chrysosporium spp.) which indicates mistakes in pasteurization. Moreover we can mention: Olive mold (Chaetomium spp.): presence of ammonia, high pH, compound too fermented, wet and compact, Chalk (Scopulariopsis fimicola): presence of ammonia, inaccurate pasteurization, excess of nitrogen and humidity of the compound and Coprinus (Coprinus spp., Trichoderma spp.) microorganism favored by excess of ammonia, high pH (±-8) and compound too wet. In addition, fungus gnat, mites and nematodes can develop if conditions persist.

Production and harvesting

A volata is defined as the sprouting of mushrooms. The average number of sprouts is 5 in the case of A. bisporus, while the period between the peaks of two sprouts is about one week. Mushrooms do not sprout with a regular pattern and their fructification is primarily evident at the edges of the beds. Usually, the first, second and third sprints are the most abundant and immediately afterwards the maximum production, as well as the total one, decreases rapidly. The quantity of mushrooms to be harvested is maximum after 3-4 days, after which the intensity of the volata gradually decreases and finally stops after a few days.

The mushrooms are harvested on the cultivation bales by hand according to size because they are delicate and break easily after harvesting are placed in suitable containers.

In order to understand whether mushrooms are ready to be harvested it is necessary to touch the inner part of the cap; in case the membrane covering the gills is elastic the mushroom is ripe, in case the membrane is torn the mushroom is too old, moreover they must have a nice light white color. When harvesting mushrooms it is recommended to delicately take the cap between fingers and remove it by slightly rotating the hand.

Consider that normally 1 sq.m. of cultivated bed is equivalent to 1 quintal of compost. So using the parameter kr/sqm and/or kr/sqm is basically the same thing.

In the years 1990-2000 up to 28 kilograms of mushrooms per square meter were produced. From 2000 to 2012 we normally produce 35 kilograms of mushrooms with peaks of 40.

However, woe betide if you don’t have the high yields mentioned above. Just think that nowadays fast cultivation cycles of 6 weeks with 3 volatas (harvests), 5 weeks with 3 volatas, 4 weeks with 2 volatas are implemented, at the operator’s choice.

I will insert the cost of a kilogram of mushrooms according to the cultivation cycles and the yield per square meter. With a cycle of 6/8 weeks and 3 spurts, with a yield of 30 kg per square meter, 1 kg costs 1.17 euros. With a yield of 31 kg per square meter, 1 kg costs 1.14 euros. With a yield of 32 kg per sqm 1 kg. costs 1.11 euros. With a yield of 33 kg per sqm 1 kg. costs 1.08 euros. With a yield of 34 kg per sqm 1 kg. costs 1.06 euros. With a yield of 35 kg per sqm 1 kg. costs 1.04 euros. With a yield of 36 kg per sqm 1 kg. costs 1.01 euros. With a yield of 37 kg per sqm 1 kg. costs 0.99 euros

From this we can deduce that having prudently based our production forecast on 27%/qle is to be considered absolutely underestimated.

Analysis of production potential

Parameters of productive calculation:

No. 12 tunnels of cultivated area of 562.50 square meters each, compost load of 600 quintals per tunnel per two months, total annual load 43,200 quintals of compost, estimated production 25/30% – Rounded prudentially to 27%, annual production mushrooms q.li 11,664, or 972 q.li month.

This is a preview, click on the button to view the full version of the document

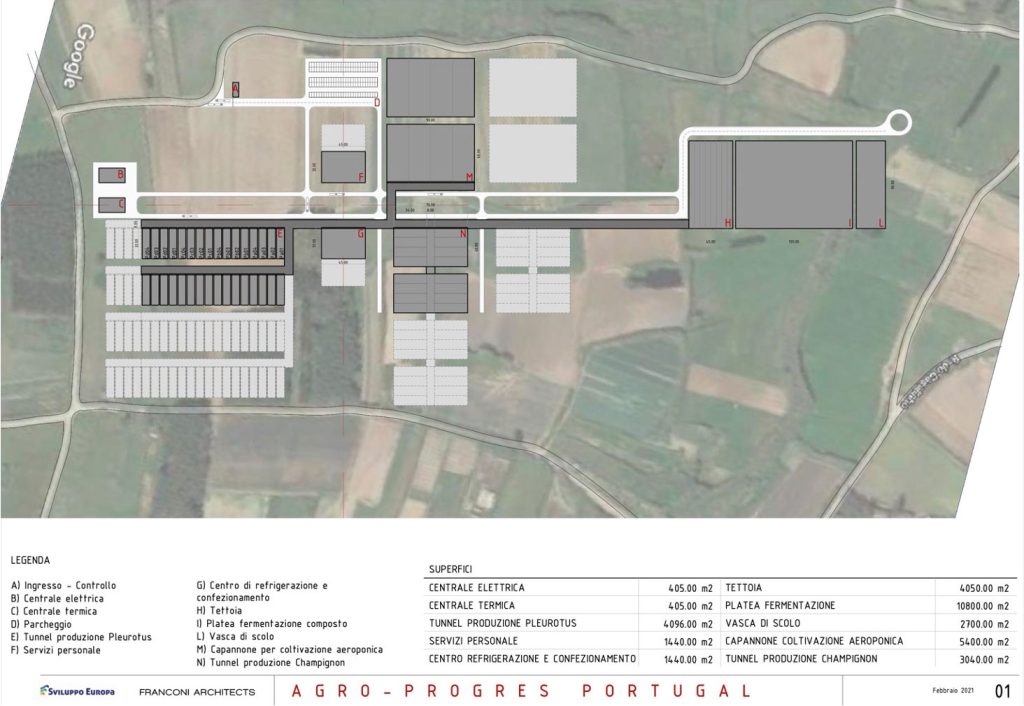

Reference is made to point G of the previously attached map, in particular, the refrigeration and packaging center covers an area of 1440 square meters.

This area, as can be easily guessed, is dedicated to the packaging of finished products and to their preservation, ready to be sold, in the many sectors of interest.

The technology unit physically comprises:

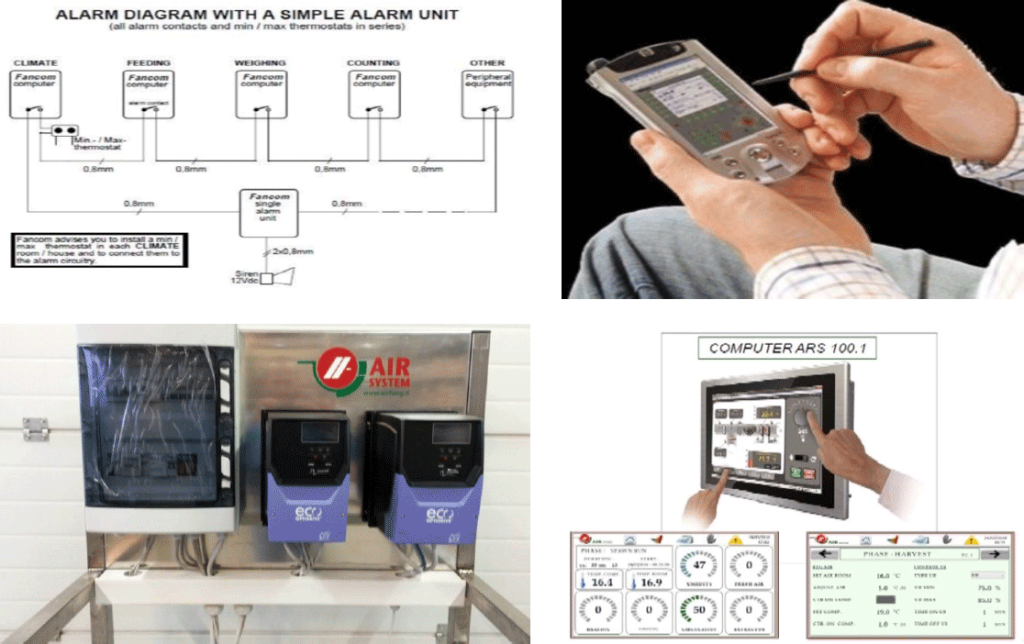

But apart from the power plants of the complex, it refers to all the various technologies used in the different stages of production. In particular, it deals with the management of ventilation, lighting, humidity and irrigation.

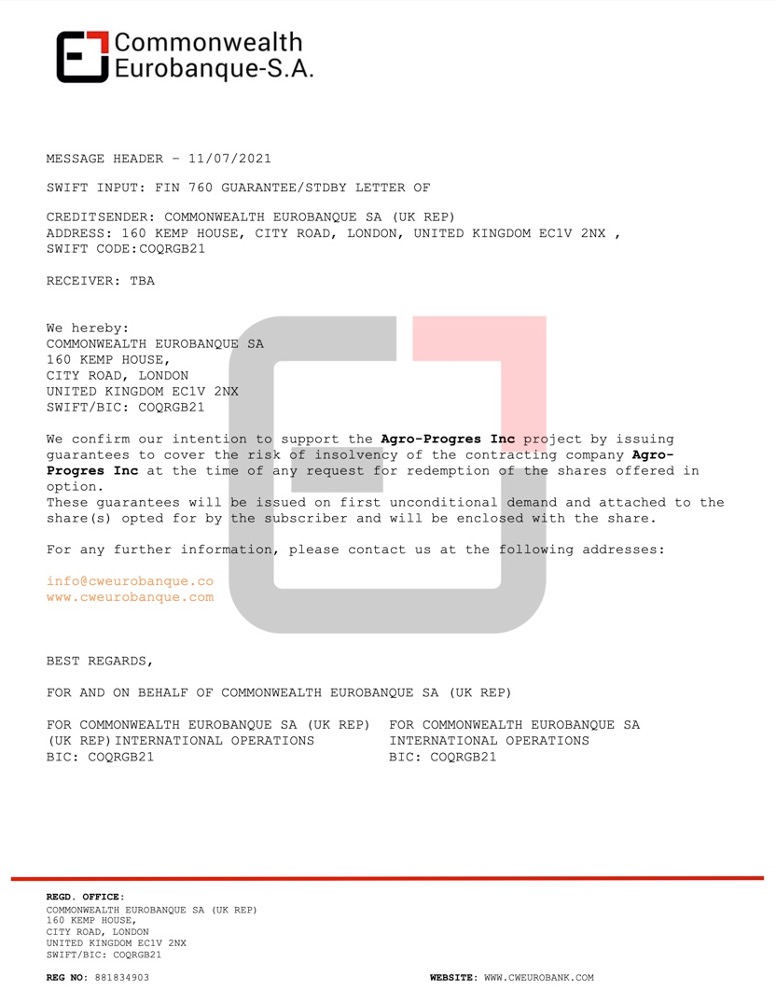

Agro-Progress Inc.: is a company incorporated under US law with share capital of € 22,000,000.00. Where 2,200 shares with a unit value of € 10,000.00 each have been issued.

These shares will have a 3-year placement, with a unit purchase price of € 7,000.00 and a final redemption of € 10,000.00.

Minimum placement package No. 10 shares.

Type of shares sold:

Shares that underlie the ownership of non-voting shareholders who, at the end of the three-year period, will be able to decide whether to remain in the company’s shareholding on a permanent basis and thus assume the status of voting shareholder, or to renounce the final subscription of the shareholding and thus request and obtain liquidation of the nominal value of the share.

Insolvency:

The risk of insolvency and therefore of eventual non-redemption of the share upon collection will be 100% covered by a specific bank guarantee, issued precisely to cover the risk of insolvency by Agro-Progres Inc as follows:

Guarantee: each non-voting share will be guaranteed, for € 10,000.00 by: COMMONWEALTH EUROBANQUE SA (UK REP),

160 KEMP HOUSE, CITY ROAD, LONDON-UNITED KINGDOM EC1V 2NX, SWIFT/BIC: COQRGB21.

http://www.cweurobank.com/

Option: at the end of the three-year period, the subscriber is free to decide whether to remain a member or to cash in the guarantee by returning it to the holding company, which undertakes to repurchase it.

This repurchase operation is guaranteed by the aforementioned Bank.

The shares opted for by the client will not be transferable in any way during the three-year period, except to the Holding Company itself, parent company of Agro-Progres Inc.

This is a preview, click on the button to view the full version of the document